The Counterfeit Detection & Authenticity Test performed by RGM SPACE is based on:

In a period of lack of materials and long lead times, purchasing counterfeited electronic parts is a risk that needs to be managed in order to avoid problems on the final product.

The safest course of action is to buy directly from the manufacturer but sometimes the provided lead times are not compatible with the project time schedule into buying readily available lots. To mitigate the risk of buying such lots, a counterfeit detection analysis is advisable.

The counterfeit detection analysis aim is to identify any possible feature that may be an indication that the received parts are different from an original unmounted part.

After a thorough documentation review, an in depth external visual inspection of the parts is carried out.

The surface, the marking and the terminations are checked to verify that everything is as expected.

Also the X-rays can be used to verify non-destructively the uniformity of the lot and the correspondence with the layout defined in the datasheet/specification.

Afterward, the device surface is tested to guarantee that it has not been reworked in any way with techniques such as remarking, resurfacing or black topping.

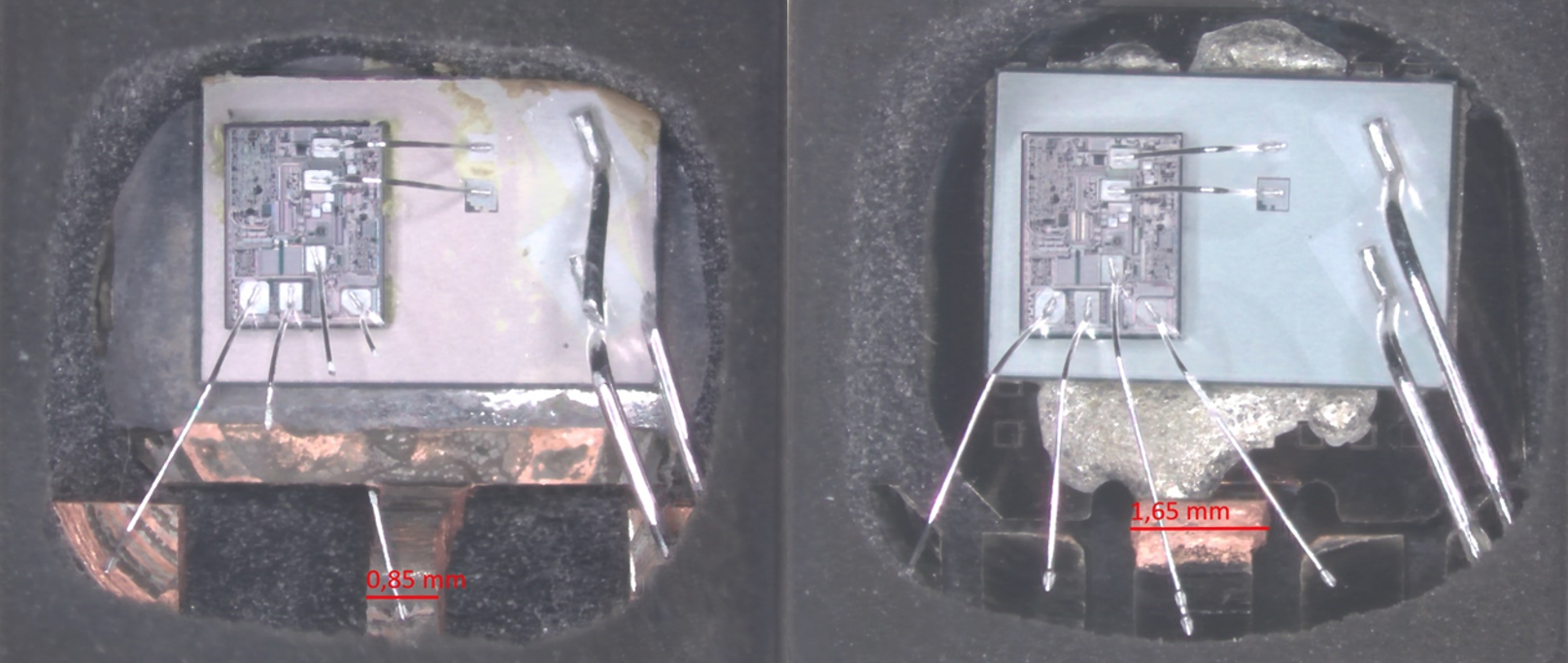

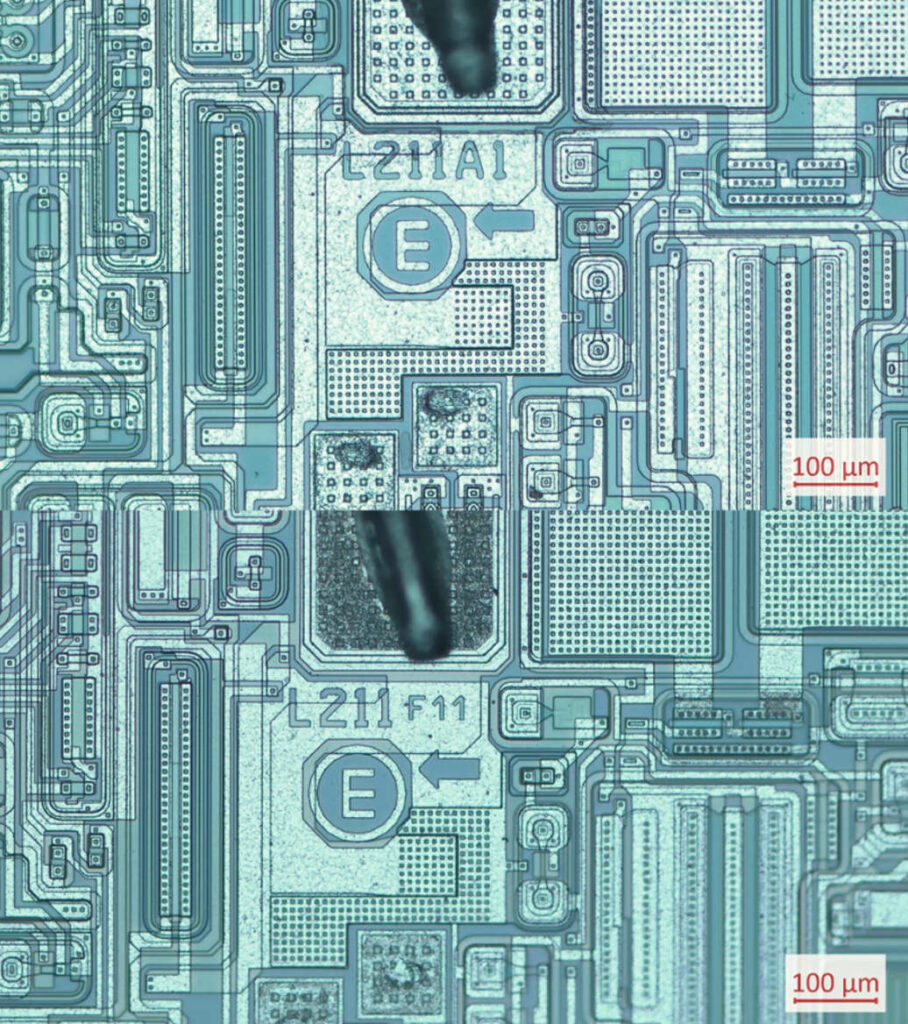

Finally, the parts are delidded/depotted to verify the originality of the die. When available, every test is compared to a golden sample.

RGM SPACE quality system is comply with guidelines SAE international per AS6081 (Fraudulent/Counterfeit Electronic Parts: Avoidance, Detection, Mitigation, and Disposition – Distributors).

Our internal procedures take into account the ESA, SAE and UNE standards.

RGM SPACE is a business unit entirely dedicated to Space that was born in Rome in 2012. The headquarter has been located in Genoa since 1986, specialised in the EEE parts components and expanding its core business not only in space but supporting also aerospace, defence, automotive, medical, railway, and industrial fields.

Tel.: +39-06-41405153

Fax: +39-06-41236539